|

|

We are MPM, Inc.

located in the Air Capital, Wichita, KS.

We are equipped with what it takes to machine difficult parts to strict tolerances.

Capabilites at a Glance

MPM, Inc.'s highly experienced personnel assure you, the customer,

the highest level of professional manufacturing service possible in Kansas.

MPM, Inc. is dedicated to providing a quality product that will meet the expectations of our customer(s) through the continual development of resources, process assessments and improvements to the effectiveness of the Quality Management System.

This is what makes MPM, Inc. one of the best companies in the Wichita area.

MPM, Inc. has teams in place to support the following functions.

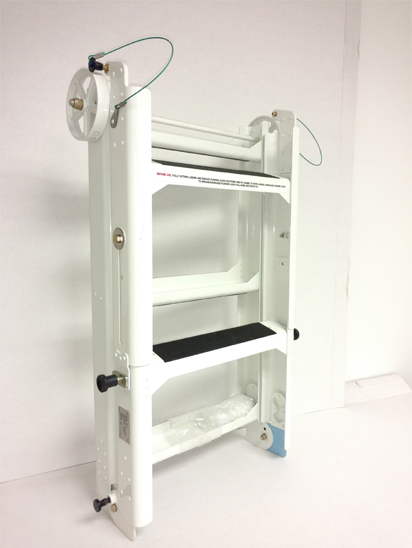

Assembly

We have a 6040 sq.ft. climate-controlled assembly room. Our team specializes in part assembly and functional testing for a variety of industries with emphasis in the aerospace industry. We conduct functional tests of the products we assemble.

Quoting

We quote all detail, assembly, tooling, and fabrication jobs. We are known for responding quickly to your needs.

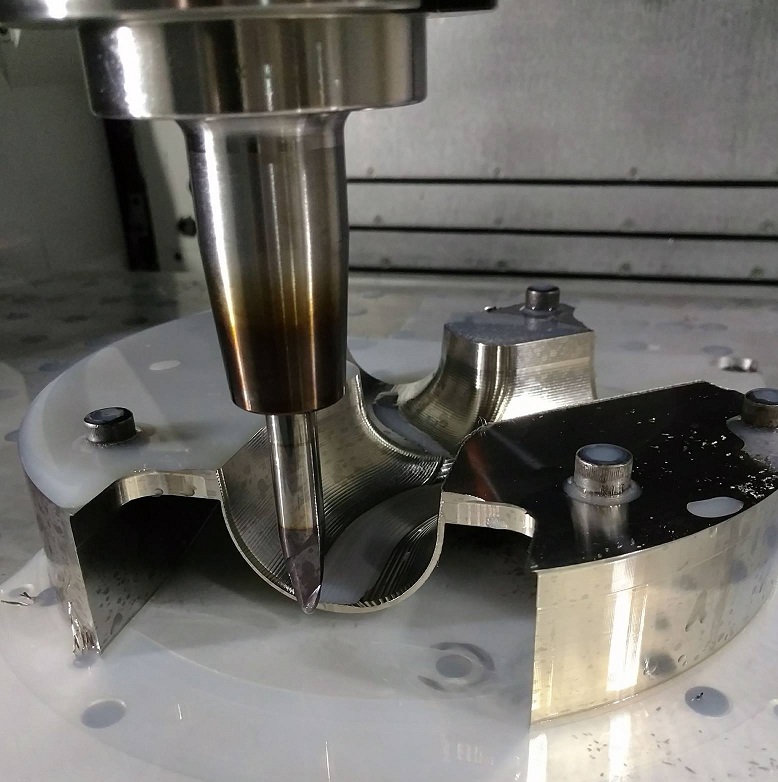

Electrical Discharge Machining [EDM]

EDM is a machining method utilized for cutting intricate contours, or delicate cavities, when traditional methods of machining cannot be used.

EDM is designed to work with materials that are electrically conductive, including Hardened Tool-Steel, Titanium, Carbide, Inconel and Kovar.

Machining

We are capable of machining 3,4 and 5 axis parts. We can machine aluminum, stainless steel, heat treated steels, titanium and many hard materials.

Planning

Our planning department is continuously looking for ways to improve our process so your parts can be delivered faster.

Programming

Catia V5 and V6

Kubotek Key Creator

Mastercam Multiaxis programming

NCL Multiaxis Machining Software, and

VERICUT

Sheet Metal

Our vast knowledge of all things sheet metal related will get your parts done, right. We specialize in hot joggle, hydroforming, and hand forming.

| 12ft CNC Break | 6ft - 65,000psi shear |

| 12” x 20” hydro press |

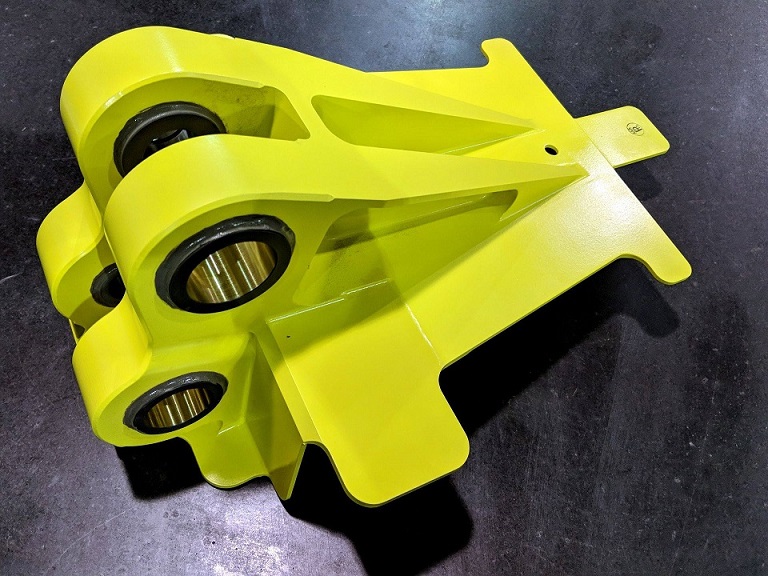

Custom Tools / Fabrication / Assembly

Our Tooling department has the capability to Reverse Engineer, Design, Machine and Assemble all of your custom tooling projects and assemblies.

| Assembly Jigs | Hydroblocks |

| Check Fixtures | Layup Tools |

| Drill Jigs | Lifting Fixtures |

| Hammer Dies | Stretch Blocks |

Machine List

Quality

Advantages of Doing business with MPM, Inc.

MPM, Inc. consistently holds tolerances down to .0005. On holes and other localized features, tolerances greater than .0005 can be achieved.

From quoting to delivery, MPM, Inc. consistently

produces some of the most difficult and quick turn jobs in the industry, including:

| • One-off Monolithic Titanium Inlet Skins for the X-45 B(IDS) |

| • Test Fuel Cell for the B-52 Replacement Fuel Bladder (IDS) |

| • Replacement Wing Spars for the KC-135 |

| • Scorpion’s 16 ft long Cockpit Rail |

| • Scorpion Pylon Shells |

| • Scorpion Canopy Rail |

MPM, Inc. has vast experience dealing with:

| • Planning Controlled |

| • Fracture Critical |

| • Fracture Critical Traceable |

| • Serialization |

| • Material and Process Traceability |

Our Products

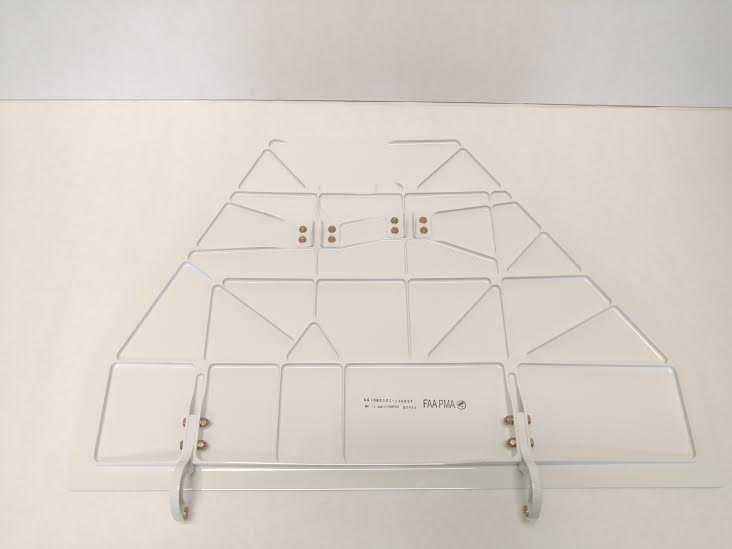

MPM, Inc. has the ability to Engineer, Fabricate and Manufacture your part to your specifications.

Inboard/Outboard Door

MPM, Inc. Designed and Manufactures both the Inboard and outboard landing gear doors. Our design removes the costly installation headaches of the other doors. Because this door is machined from a solid block, this door contains NO spot welds, rivets or stretch forming. These doors are PMA/FAA approved worldwide and have been part of the OEM aircraft installation since December 2000.